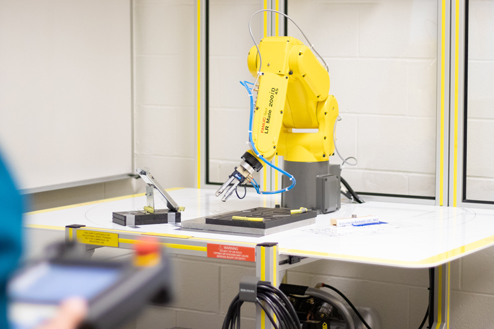

On March 26, CBT and Rockwell Automation participated in the ribbon cutting ceremony for the new Mechatronics Lab at Northern Kentucky University. The lab is decked out in the latest industrial automation technology allowing mechatronics and engineering majors to participate in hands-on learning to better prepare them for real life situations.

Skills Gap

“When I sit down with the owners and leaders of our regional customers, the number one issue they have is finding qualified people to troubleshoot and implement new solutions within their facilities. The next generation is just not trained yet on the technology,” said CBT Senior Vice President, Jay Stahl. Manufacturing job openings have been growing at double-digit rates since mid-2017, due to economic expansion and the retirement of the baby boomer generation, but the number of qualified candidates has been steadily decreasing.

Mechatronics is a field that blends data analytics, computer programming, engineering and robotics into one.The lab provides a real industrial automation environment with ten workstations that enable students to assemble, program, and operate integrated manufacturing systems. NKU is the first in the region to offer a four-year degree in the field, and the new lab will ensure students are ready to enter the workforce upon graduation.

The Mechatronics Lab at NKU will help draw more students to the field by showing the exciting new technologies present today. “Automation and robotics are the future of industry, and we must ensure our graduates are ready on day one with the skills and competencies to fill this employment gap,” said NKU president, Ashish Vaidya. The Mechatronics Lab is fully equipped with ten workstations with hands-on demos in fixed automation like that in a standard conveyor belt transfer line. Students will also practice flexible automation, where they will use PLCs to program material handling devices, robots, and machines to do a range of tasks. The lab is fully capable of expanding and evolving as technology continues to advance.

Industry Needs

“Local companies like Amazon, FedEx, and DHL are investing here to build hubs and distribution centers, and they will  continue to expand. Engineers are needed to design and build the control systems for these centers, and technologists to run them,” said Mike Schutte from Rockwell Automation. The possibilities are endless for those with an engineering or mechatronics degree, but it’s all about shifting the mindset of K-12 students and enabling them to envision their potential in the manufacturing sector.

continue to expand. Engineers are needed to design and build the control systems for these centers, and technologists to run them,” said Mike Schutte from Rockwell Automation. The possibilities are endless for those with an engineering or mechatronics degree, but it’s all about shifting the mindset of K-12 students and enabling them to envision their potential in the manufacturing sector.

“The roles in the field of industrial automation that NKU is preparing their students to succeed in are not what many would consider to be traditional manufacturing jobs” said Stahl. “Individuals who have the ability to troubleshoot, implement, and upgrade automation solutions within the strong manufacturing base in our region will graduate with good paying job opportunities and an excellent career path. The continued focus on automation to improve efficiencies in manufacturing will create an even higher demand for these unique skill sets in the future.”

CBT has recognized the impact of the skill gap on our customers in the region, and we are honored to have been involved in the development of this project at NKU. We know that the graduates of this program will be welcomed with open arms at the companies they will join in the future due to their knowledge and experience with the advanced manufacturing technology provided in the new Mechatronics Lab. Congratulations to all those involved on this project, we can’t wait to see how everything develops in the future.