Leak Detection Audit

Leak Detection Audit

HIDDEN LEAKS CAN BECOME A HUGE PROBLEM

Spotting air leaks in your facility can be tricky. Beyond performance issues and increased energy consumption, the damage caused by unnoticed gas or compressed air leaks can be substantial and long-term. Our Specialists conduct leak detection audits to reduce downtime and operating costs. Using the latest thermal imaging equipment, we thoroughly inspect your facility, taking note of any possible steam, compressed air, gas, or other pressured distribution leaks.

Interested in learning how a leading chemical company saved more than $1 million through an easy leak detection audit?

BENEFITS OF A LEAK DETECTION AUDIT

Energy Efficiency & Savings

Leaks in a system can create insufficient flow, causing equipment to malfunction. Leaks can also cause excessive cycling of compressors leading to higher utility charges and excess wear on compressors. Detection audits identify costly leaks for repair, allowing your equipment to operate as efficiently as possible and reducing your operating expenses.

A Thorough Understanding of Your Issue

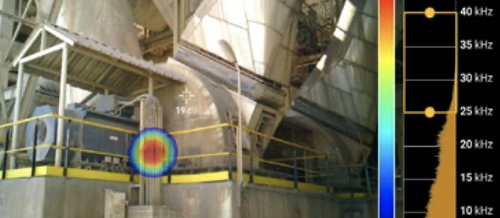

CBT utilizes state-of-the-art technology to find leaks in compressed air, gas, and vacuum systems. With tools such as the Fluke ii900, Specialists can provide comprehensive photos and videos of leaks, and a scale measuring leak severity.

A Resolution to Your Problems

A Specialist will survey the air/gas delivery systems in your facility. Identified leaks will be tagged for easy identification. Upon completion of the on-site audit, a report will be generated that includes the following for all leaks: a photo of the leak, tag number, location, severity, and estimated repair/replace cost.