- Who We Are

- About Us

- Line Card

- Our History

You have no items in your shopping cart.

You have no items in your shopping cart.

- Resources Resources At The Ready

- AIRpipe

- Bearings & Seals

- Belting & Conveyor

- Belts & Pulleys

- Bushings & Shaft Accessories

- Clutches, Brakes, Tension Control

- Conduit, Fittings & Electrical Boxes

- Couplings

- Enclosures

- Energy Management

- Facility Maintenance

- Gears & Gear Reducers

- Lighting

- Linear Components

- Material Handling

- Motor Control & Load Protection

- Motors

- Networks & Communications

- PLC & Operator Interface

- Plugs, Receptacles, & Switches

- Pneumatics

- Power Distribution

- Power Supplies

- Pushbuttons, Selector Switches & Pilot Lights

- Relays & Timers

- Safety

- Sensors, Encoders & Limit Switches

- Servo & Stepper

- Signaling Devices & Beacons

- Sprockets & Chain

- Training

- Wiring, Cable & Cable Management

- Who We Are

- About Us

- Line Card

- Our History

- Configurator & Part Selection

- CBT Belt Configurator

- Gates Configurator

- Rockwell Configurator

- Customer

- Credit Application

- FAQs

- Locations & Hours

- Resources

- Resources At The Ready

- Training

- Rockwell Learning+

- Training Schedule

- AIRpipe

- Bearings & Seals

- Belting & Conveyor

- Belts & Pulleys

- Bushings & Shaft Accessories

- Clutches, Brakes, Tension Control

- Conduit, Fittings & Electrical Boxes

- Couplings

- Enclosures

- Energy Management

- Facility Maintenance

- Gears & Gear Reducers

- Lighting

- Linear Components

- Material Handling

- Motor Control & Load Protection

- Motors

- Networks & Communications

- PLC & Operator Interface

- Plugs, Receptacles, & Switches

- Pneumatics

- Power Distribution

- Power Supplies

- Pushbuttons, Selector Switches & Pilot Lights

- Relays & Timers

- Safety

- Sensors, Encoders & Limit Switches

- Servo & Stepper

- Signaling Devices & Beacons

- Sprockets & Chain

- Training

- Wiring, Cable & Cable Management

- Who We Are

- About Us

- Line Card

- Our History

- Configurator & Part Selection

- CBT Belt Configurator

- Gates Configurator

- Rockwell Configurator

- Customer

- Credit Application

- FAQs

- Locations & Hours

- Resources

- Resources At The Ready

- Training

- Rockwell Learning+

- Training Schedule

Lockout/Tagout

Lockout/Tagout

Lockout/tagout (LOTO) is a safety procedure that isolates energy sources to prevent unexpected startup or accidents that could cause injury. Machinery and equipment with lockout/tagout devices ensure no one can use them until all safety or maintenance issues are solved.

SAFETY PROCEDURES

OSHA requires LOTO procedures to be stringently followed by employees who work on, near, or with systems that use electric energy. Compliance with lockout/tagout rules prevents 120 fatalities and 50,000 injuries annually. Proper facility personnel can review a fully comprehensive lockout/tagout plan for gaps, deficiencies, and flaws.

AUDITS

Creating a procedural plan is a great place to start, but scheduling a regular review to determine if LOTO procedures still comply with the most recent guidelines is vital. Audits are a crucial component of a comprehensive LOTO program – along with equipment-specific strategies, employee training, a corporate policy, and adequate devices. A thorough audit will ensure your LOTO procedures remain compliant with changing regulations.

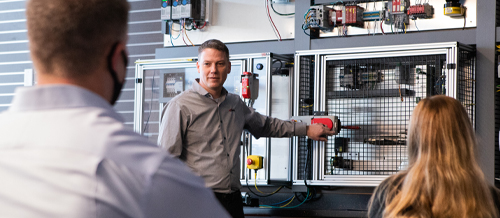

TRAINING

Enhance your company’s compliance with custom LOTO training. Whether you have recently hired or experienced employees, this training program will expand your employees knowledge of the LOTO standards. OSHA requires LOTO audits and employee certification at least once a year to ensure your training meets the most up-to-date standards.

Learn More>>

Learn More>>

Need to review and update your lockout/tagout procedures? Contact a Specialist today.

CONTACT US

SITE INFO

Copyright © 2026 CBT Company. All rights reserved.