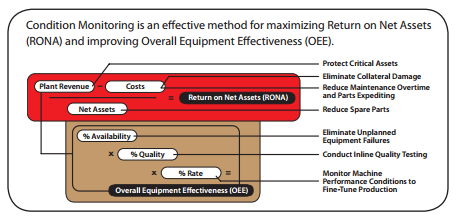

Condition monitoring increases the overall knowledge of asset condition. It allows decision makers to perform Condition-based Maintenance (CbM) by scheduling downtime, labor, and materials based on machinery health. However, many companies cannot reap the benefits of an effective CbM program because they don’t have the knowledge or resources to do so. With Rockwell Automation and CBT Condition Monitoring Services, you will receive tailored solutions to help you implement your CbM program and use our field of specialists to help you succeed. The goal of a world-class CbM program is to increase the reliability and availability of your machinery, while minimizing downtime, labor, and repair costs. The results are dramatic and the documented cost savings are significant. CbM programs are proven to be effective when multi-technology strategies are considered.

Condition monitoring increases the overall knowledge of asset condition. It allows decision makers to perform Condition-based Maintenance (CbM) by scheduling downtime, labor, and materials based on machinery health. However, many companies cannot reap the benefits of an effective CbM program because they don’t have the knowledge or resources to do so. With Rockwell Automation and CBT Condition Monitoring Services, you will receive tailored solutions to help you implement your CbM program and use our field of specialists to help you succeed. The goal of a world-class CbM program is to increase the reliability and availability of your machinery, while minimizing downtime, labor, and repair costs. The results are dramatic and the documented cost savings are significant. CbM programs are proven to be effective when multi-technology strategies are considered.

Vibration Analysis

- Measures the change in vibration intensity on mechanical equipment when machine condition begins to degrade

Oil Analysis

- Detects contamination or degradation of oil which indicates machine wear

Infrared Themography

- Detects variations of apparent temperatures in electrical, mechanical, infrastructure, and process equipment.

After the analysis have been completed, we will provide you with a complete predictive maintenance program solution customized to fit your facility and its specific needs. When determining the type of program you want, you should consider the resources you need to run the program, the rate in which your machines fail, or the loss of production due to a machine failure. Once you decide if you are in sourcing or outsourcing, Rockwell Automation and CBT can Condition Monitoring Services to fit your budget. Contact your client services specialist to get started today.