Get Custom Enclosures Faster With CBT’S Automated Modcenter

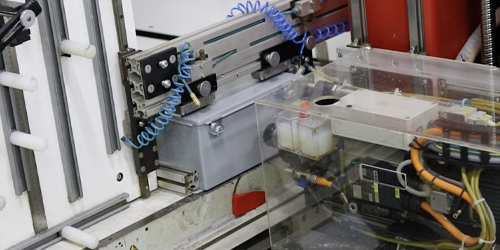

In an increasingly automated world, the process of enclosure modification has remained relatively manual. Measuring, drilling, and cutting can take upwards of four hours per panel and ultimately yield imperfect cuts. CBT’s ModCenter powered by nVent HOFFMAN takes the guesswork out of manual modifications and converts project timelines from weeks to days.

FEATURES & BENEFITS:

FEATURES & BENEFITS:

- Eliminates paper drawings on plant floor to produce professional, repeatable holes and cutouts

- No deburring needed and able to produce most cutouts on most materials

- Mitigates equipment misalignment

- CBT has local inventory of the most popular nVent HOFFMAN enclosures

- Performs all necessary drilling, milling, tapping, and engraving

- Designed-in library of Rockwell Automation Parts to ensure proper fit of your equipment

- Skilled ModCenter experts can design enclosures ideal for your application

By eliminating the need to manually measure, drill, tap, and process, the time for each panel is reduced to about 30 minutes* – 87% less than if done manually.

*Hoffman Pentair Panel Shop Case Study

Increase Productivity

CBT’s ModCenter can drastically reduce project times, allowing employees to dedicate their time and skills on higher-value skilled tasks.

CBT’s ModCenter can drastically reduce project times, allowing employees to dedicate their time and skills on higher-value skilled tasks.

Improve Safety

Eliminate the safety risks that come with employees manually cutting and drilling into stainless steel and other metals.

Eliminate the safety risks that come with employees manually cutting and drilling into stainless steel and other metals.

Increase Throughput

CAD drawing imports and machined precision eliminate manual error and reduce material waste, resulting in cleaner, more professional modifications.

CAD drawing imports and machined precision eliminate manual error and reduce material waste, resulting in cleaner, more professional modifications.

Reduce Operating Costs

Save up to 87% in time and cost when comparing CBT’s ModCenter to an enclosure modified by hand.

Save up to 87% in time and cost when comparing CBT’s ModCenter to an enclosure modified by hand.